The following is a review of the development history of China's wire rope standards, combined with the dimensions of technological evolution, industrial upgrading and international cooperation:

I. Initial stage (1950s-1970s): Soviet model reference and primary system construction

Standardization foundation establishment

In the early 1950s, my country's wire rope standards mainly followed the Soviet model, separating the variety structure from the technical conditions standard, forming early national standards and Ministry of Metallurgy standards47.

In 1939, Tianjin No. 1 Wire Rope Factory was completed and put into production, becoming the first metal products enterprise in China, marking the beginning of industrialized production.

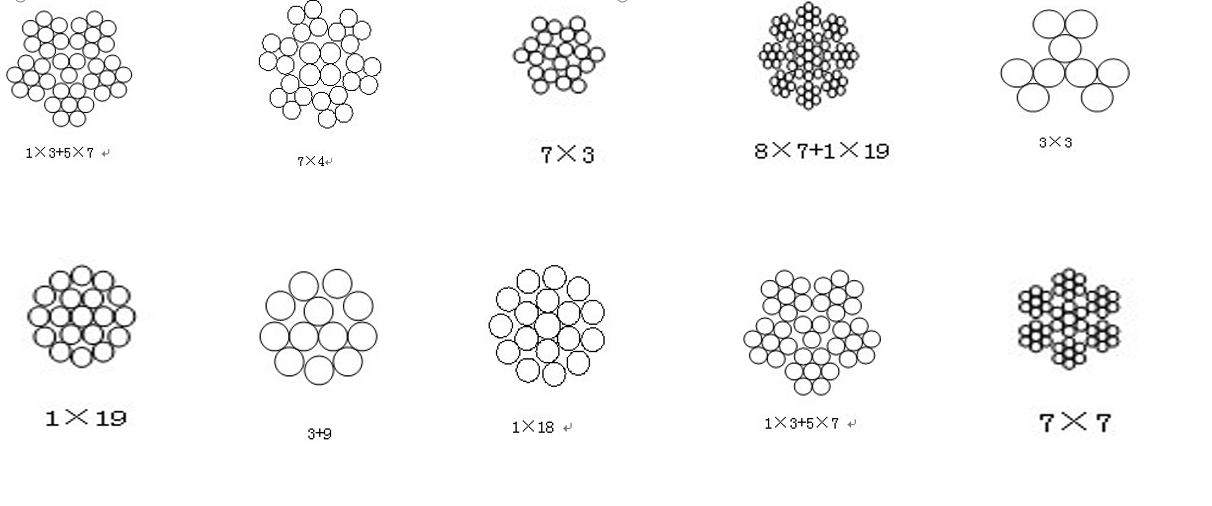

Classification system prototype

In the 1970s, the standards were redrafted, classified by use or structure, and a standard system consisting of round strands, sealed strands, special-shaped strands, aviation and elevator wire ropes was initially constructed.

II. Improvement stage (1980s-2000s): Deepening of the standardization system and international integration

System framework matures

After 1985, a complete standard system consisting of basic standards, product standards, test methods, and packaging acceptance was formed, covering the entire life cycle management.

In the 1990s, the product structure was upgraded, transitioning from point contact to line contact and surface contact, improving wear and corrosion resistance.

International Standards Introduced

After 2000, the country accelerated its integration with the international community, and the national and industry standards formulated and revised covered emerging fields such as high-speed rail, wind power, and bridges to meet diversified needs45.

3. Breakthrough stage (2010s-2020s): Independent innovation and enhanced international discourse power

International standards dominate

In 2017, the ISO 2408:2017 "Wire Rope - Requirements" drafted by Lu Ping's team was released globally, becoming China's first international standard for wire ropes, breaking the long-term monopoly of Europe and the United States.

The standard took 5 years to develop, and key data was obtained through innovative research and development of 264mm diameter super-large wire ropes, promoting Chinese companies to participate in international competition.

Industry application deepening

High-speed rail field: In 2008, Farsen Hongsheng Group developed stainless steel and carbon steel composite structural steel wire rope, which was applied to the "eight vertical and eight horizontal" high-speed rail trunk lines, with a cumulative supply of more than 6,000 tons and a market share of 90%35.

In 2024, it will take the lead in formulating the industry standard "Composite steel wire rope for compensation of electrified railway contact network" (YB/T 6295-2024), further consolidating its technological leadership5.

IV. Intelligent and green stage (2020s to present): high-quality development transformation

Technology upgrade direction

Develop high-end products such as wind power mooring cables and deep-sea engineering ropes, and promote the localization of large-scale equipment25.

Strengthen material properties, such as the tensile strength of stainless steel wire ropes increased to 1970N/mm², and the diameter range expanded to 6-83mm, to meet the needs of extreme working conditions.

Standard Ecosystem Construction

A linkage mechanism of "national standards-industry standards-international standards" has been formed. Guizhou Wire Rope, Farsen and other companies have participated in the formulation and revision of more than 73 standards, covering the entire industry chain.

Summary

China's wire rope standards have gone through four stages: imitation and exploration→system improvement→independent innovation→global leadership. Through technology iteration and internationalization of standards, it has supported the development of strategic industries such as high-speed rail, wind power, and marine engineering. In the future, we need to continue to focus on green manufacturing, intelligent testing and other fields to promote collaborative innovation of standards and technologies